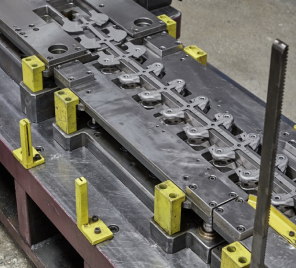

Stamping

Progressive and transfer stamping press up to 800 tons / 3.2 meters table sizes, giving us an advantage to produce mid and big size components to serve our customers in our existing Turkey locations.

We continue to invest new press technologies together with 1200 tons transfer press addition to our new plant in Romania which will have 6 meters table size. We are capable of processing 1250 mm strip-coils width and 0.5 mm to 6 mm thickness in various sizes even with the height strength values with a grade up to DP1000.